The Engineering and Physical Sciences Research Council (EPSRC) have awarded the Astrophyics Group in the Cavendish laboratory a £900k grant to develop a new precision manufacturing technology, based on technology we developed to equalise the optical paths in arrays of telescopes. Over the past 25 years, precision manufacturing has become a core technology enabling the market growth of thousands of products. Smartphones, digital imagers, and even medical implants depend upon precision manufacturing with tolerances at the micron or sub-micron level. While tolerances at the nanometre level are possible using techniques such as electron-beam lithography, these tolerances can usually only be maintained over distances measured in millimetres. In this initiative, we will develop the technology to push manufacturing at nanometre precision to allow it to maintain this precision over metre scales.

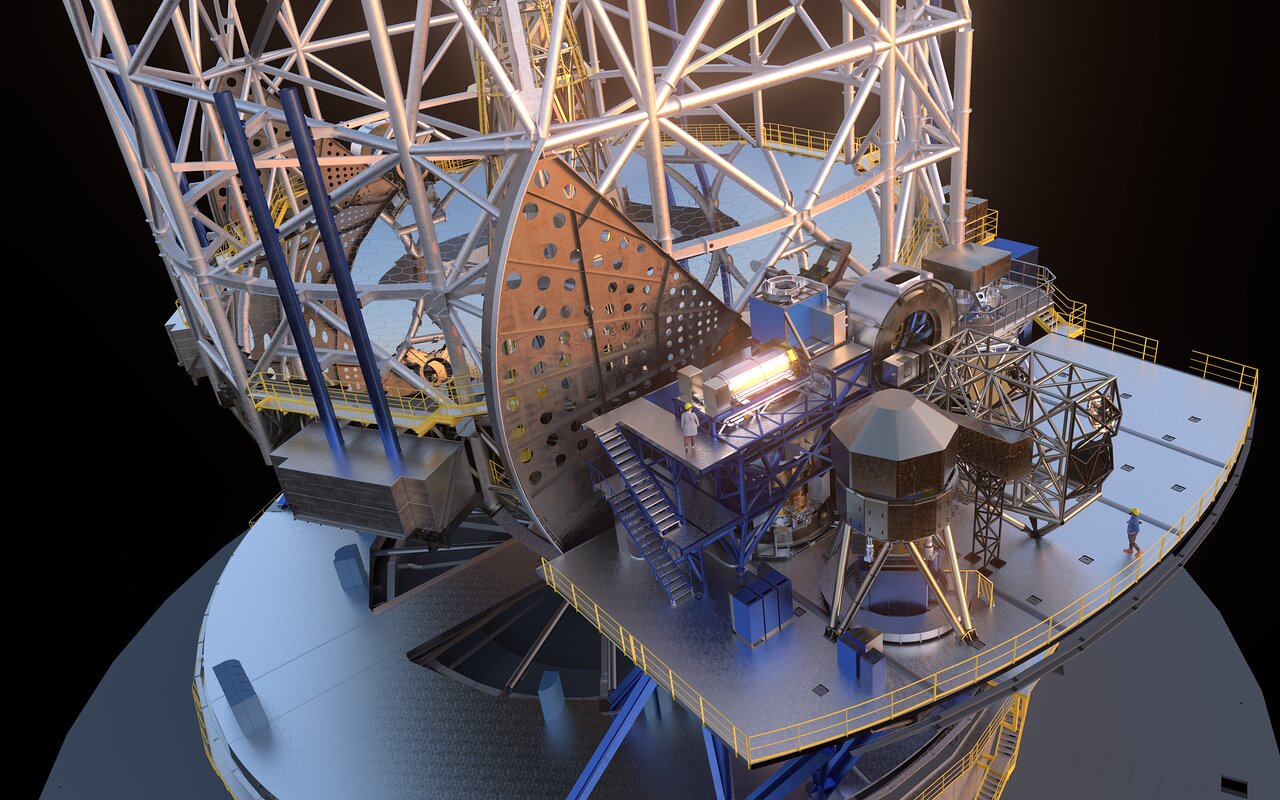

The first target for this new precision manufacturing technique is the manufacture of diffraction gratings for spectroscopy on Extremely Large Telescopes (ELTs) such as the European ELT (E-ELT).

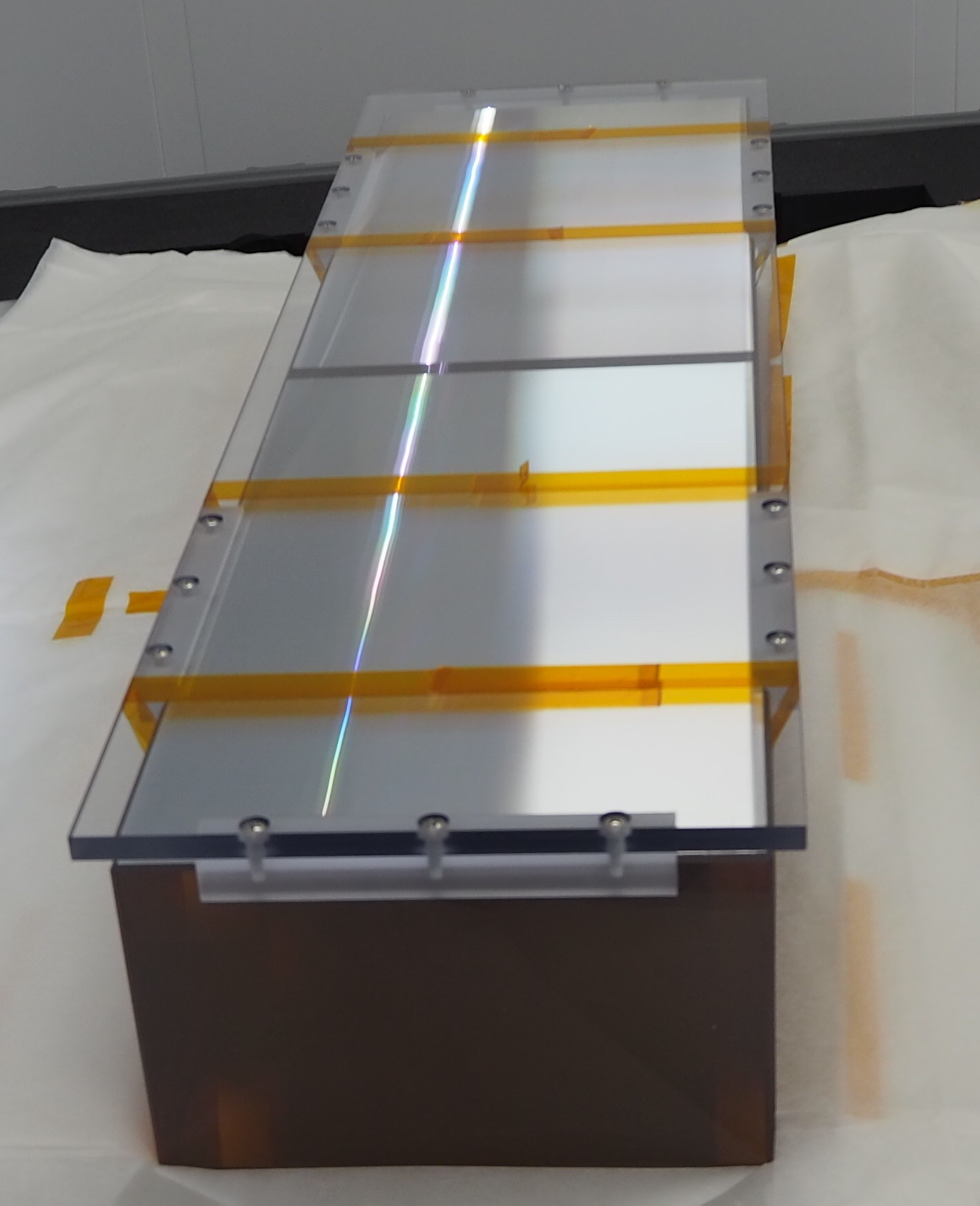

Spectrographs are the workhorse of astronomy and depend upon the use of diffraction gratings to split starlight into tens or hundreds of thousands of spectral channels. These gratings consist of a large set of parallel finely-spaced grooves manufactured to precisions measured in nanometres. For the upcoming generation of astronomical telescopes with primary mirror diameters of tens of metres, the gratings needed are typically metres in size.

To solve the manufacturing challenge of nanometre precision over metre scales requires a combination of two new technologies. The first is that of manufacturing nanostructures in silicon using wet etching. This has been used by groups such as Dr Uwe Zeitner’s group at the Fraunhofer Institute in Jena to make centimetre-sized silicon gratings with exquisite accuracy.

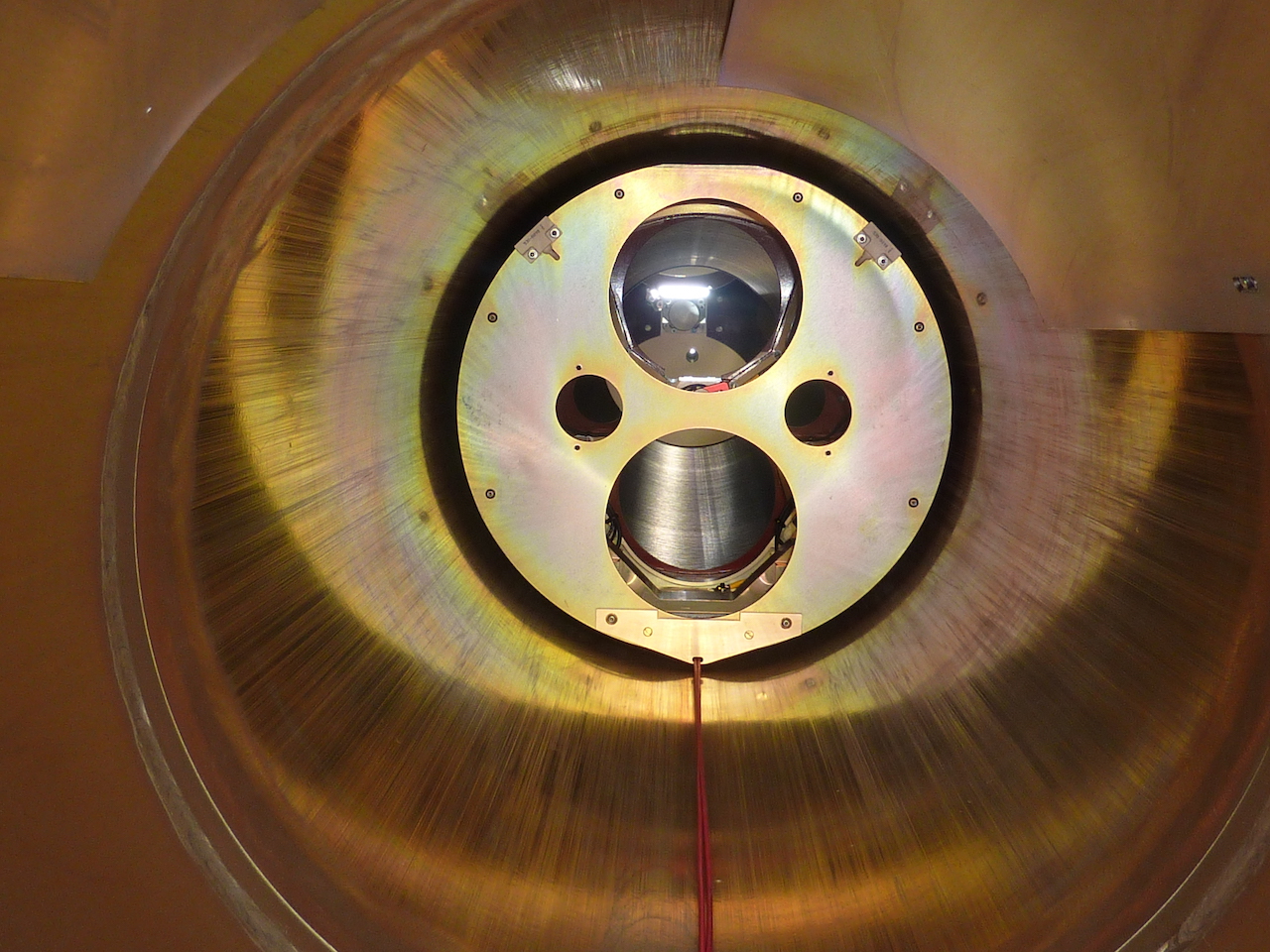

The second technology is based on the delay lines we have developed for use in optical interferometers such as the Magdalena Ridge Observatory Interferometer (MROI). Optical interferometers are arrays of telescopes used to observe astronomical targets at scales much finer than possible using conventional telescopes such as the Hubble Space Telescope. The delay lines are used to equalise the optical paths between telescopes in the array, and involve moving mirrors precisely over distances of hundreds of metres.

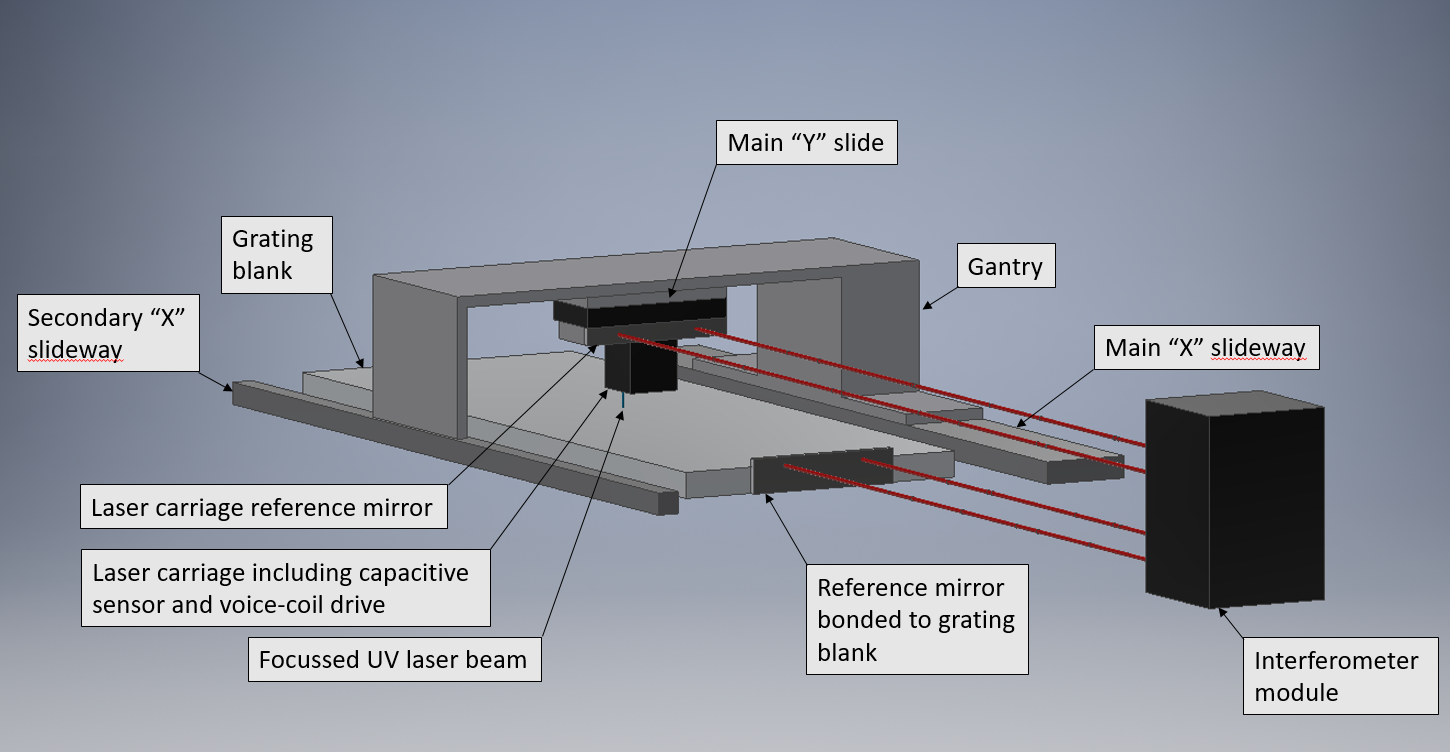

We will use the technology used in our delay lines to build a precision “lithography engine”, capable of patterning silicon substrates over metre scales with nanometre precision. The lithography engine will “write” patterns on to photoresist-coated silicon wafers using a “floating head” whose position is precisely controlled with the aid of laser metrology. The patterned silicon will then be processed by Zeitner’s group to yield large, accurate gratings.

We will use the technologies developed here in the shorter term to address an immediate need in astronomy for metre-scale diffraction gratings, but the lithography engine we are developing can serve as the basis of a more widespread revolution in precision manufacturing. Unlike other grating-patterning technologies which project stripe-shaped interference patterns onto a substrate, our lithography engine architecture can be straightforwardly extended to allow arbitrary two-dimensional patterning over metre scales while maintaining nanometre-level accuracy. Exploring the manufacturing applications of such an extended capability is the longer-term goal of our programme.